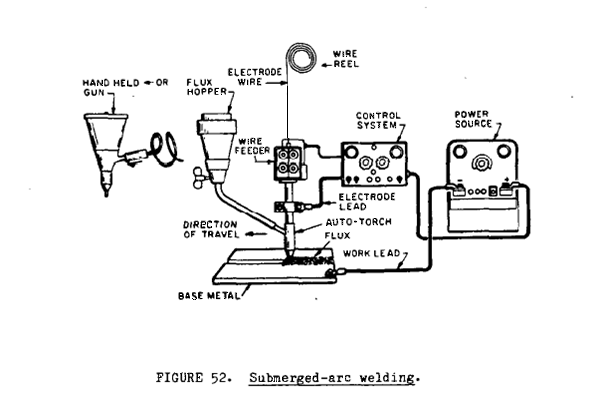

In submerged arc welding (SAW), a continuous

wire electrode is fed into a mound of granular flux that covers the joint. The

welding head is traversed mechanically along the joint and flux is added

continuously. The arc causes the base metal,

electrode, and flux in the immediately vicinity to melt. The

malted base material and filler flow together in the joint. At the same time,

the melted flux floats on the surface, forming a protective slag. Since the arc

runs beneath the flux covering without sparks, smoke, or flash, the operator

needs little protective equipment.